簡介:An Tech公司最近發(fā)布一款產品,能夠在高壓深水海洋管柱布置作業(yè)中檢測管柱接頭。該系統(tǒng)使用磁場法來檢測。

AnTech has recently unveiled a sensor that promises to “see through steel.” The company’s Triple Sensor Tool Joint System, or MDET-S, is a new sensor technology designed to automatically detect tool joints in risers during the deployment of tubing strings in high-pressure, deepwater fields.

The new system detects tool joints by measuring changes in magnetic fields that are triggered when a joint passes through the field. It was developed to improve the safety and efficiency of deploying tubing strings under pressure for an oilfield-service provider performing well-intervention operations in the US Gulf of Mexico.

The service company will employ the MDET-S in a deepwater, high-pressure field situated in more than 6,000 ft of water that is being developed using a permanently moored semisubmersible production and drilling facility.

To support the well-intervention activities for this deepwater field, AnTech’s client developed a hydraulic workover (HWO) system, which is located under the rig floor with heave compensation provided by the rig’s riser-tensioning system. Special rig-assist HWO equipment, combined with a purpose-built blowout preventer (BOP) stack, are being used to deploy the tubing strings under pressure.

To ensure that string deployment is carried out safely, a technician must know when the tool joints are correctly located within the BOP stack so that the joint can be passed through the set of pressure seals into or out of the wellbore. Locating tool joints and positioning the tubing string has traditionally been done manually, a laborious exercise that carries some safety risks to the technician.

The MDET-S, therefore, was born out of a need to replace this manual method with a device that could automatically detect tool joints and alert the technician when the joint had moved into the field of sensors.

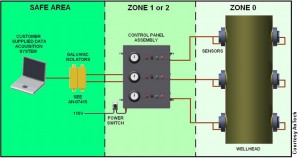

AnTech drew on its 16-year history of developing and manufacturing magnetic wellhead sensors for deepwater operations during the development of the MDET-S. To accommodate the magnitude of the new deepwater installation, the company designed the system with three sets of two sensors, which detect changes in the surrounding magnetic field brought about by the additional thickness of the metal joint as it passes through the field. No markers are required on the pipe joints for this measurement.

Once the sensors detect this shift in the magnetic field, they emit an electrical signal which is transmitted to a control box. The box alerts the technician that a tool joint has passed by a pair of sensors, and additionally transmits digital and analog signals to an external data-acquisition system that transfers the readings to a file located on the technician’s laptop. The technician can then analyze this data and proceed, certain that the tool joint has reached its target destination.

“The MDET-S makes it possible for engineers to effectively ’see through steel’ without manually measuring and identifying their location visually,” said Toni Miszewski, managing director of AnTech. “With its ability to pinpoint the location of the tool joint through shifts in the magnetic fields surrounding the sensors, the entire process is much safer and efficient, as well as more reliable.”

For further information, contact Toni Miszewski at +44 (0)1392 440 300 or by email. Additional information can also be found at www.antech.co.uk.

楊寶劍 是振威(全球)石油網的高級技術編輯,在石油技術資訊行業(yè)有八年的學識和經驗。他源源不斷地提供石油行業(yè)全球最新的技術創(chuàng)新、研發(fā)成果、現(xiàn)場應用情況等信息。如果你對該項新技術有任何的疑問,或者對“新技術新產品”未來的內容有任何問題或建議,請聯(lián)系楊寶劍編輯 +86 10-58236512 Email:allenyo@zhenweiexpo.com 歡迎與行業(yè)互動!